What is Advanced Analytics?

Advanced Analytics is the evolution of data analysis, combining sophisticated techniques such as Artificial Intelligence (AI), Machine Learning (ML), and statistical modeling to uncover deeper insights, predict future trends, and optimize decision-making.

Our team transforms your data into a powerful strategic asset, helping your organization react to changes in real time, shape strategies for the future, and innovate.

How Advanced Analytics Drives ROI

Advanced Analytics empowers businesses to act rather than react, unlocking new growth and long-term impact.

By simulating “what-if” scenarios, Advanced Analytics proactively manages risk and minimizes disruptions, helping organizations stay ahead of change.

Trust us to help you uncover new revenue opportunities and deliver personalized experiences at scale.

Our Solutions

Forecasting

Measure Tomorrow with Precision.

Forecast future trends in sales, operations, and finance with precision and confidence, minimizing risk and enabling informed strategic planning.

Our AI-driven software adapts to your unique needs, ensuring that your forecasts are accurate, actionable, and easy to implement across your organization.

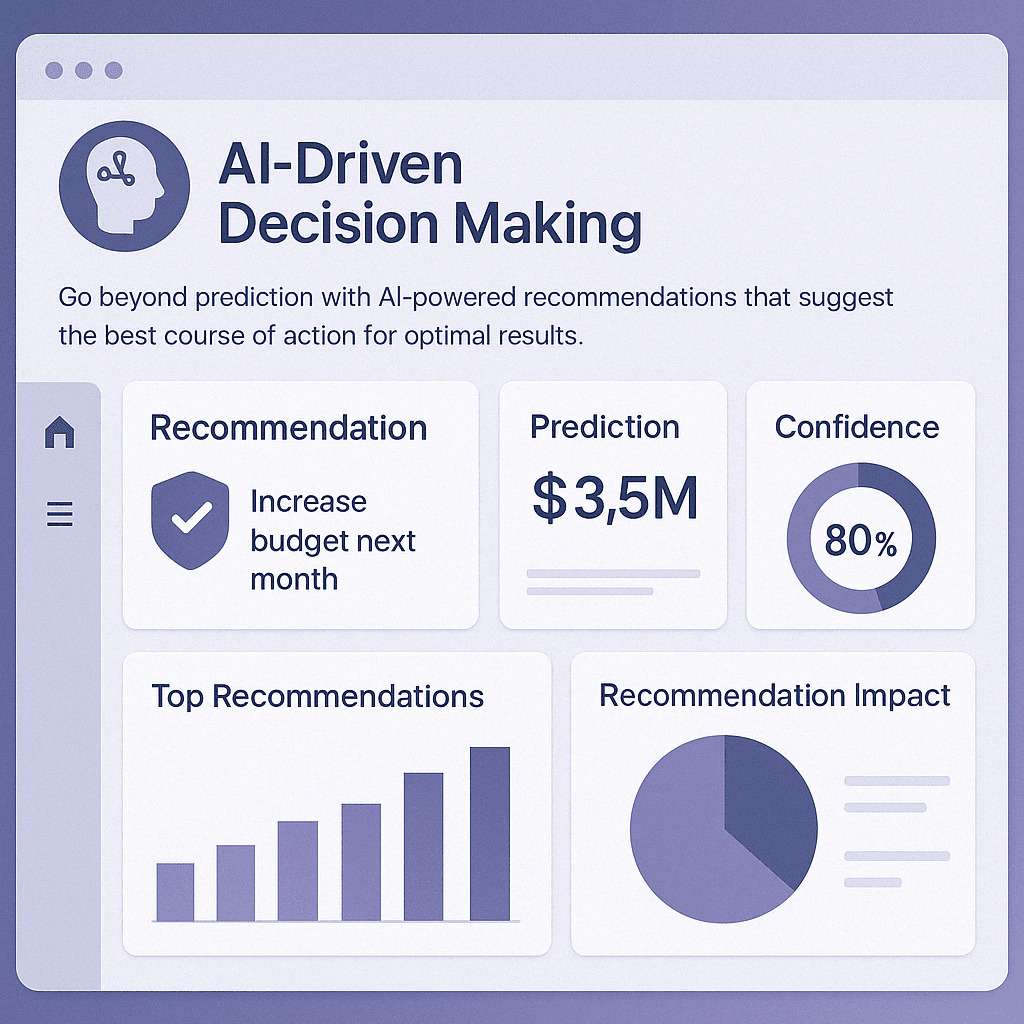

AI-Driven Decision-Making

Go beyond prediction with AI-powered recommendations that suggest the best course of action for optimal results.

AI-driven decision-making doesn’t just tell what might happen; it provides data-driven insights on what to do next, ensuring that our decisions are optimized for maximum efficiency and impact.

Optimization Solutions

Enhance your supply chain (SC) and operations by leveraging advanced algorithms to minimize costs, improve services, and boost speed.

Our optimization solutions empower your organization and enhance business value by using highly sophisticated AI-driven methodologies.

Agent-AI & Auto-ML

Automate complex processes and uncover deeper insights with cutting-edge AI and machine learning models tailored to your industry needs.

No matter where you are in your analytics journey, WITSIDE’s services are designed to drive impactful results across your organization by using the latest methodologies and infrastructure.

Case Studies

See how we’ve helped companies in Greece and abroad achieve digital transformation across leading industries, including energy, oil & gas, retail, and tourism.

- BI, Data Management

- Advanced Analytics

- BI, Data Management

Transform Your Data with WITSIDE’s AI and ML Solutions

Unlock the next level of data-driven innovation by integrating AI capabilities into your analytics strategy.

Our expert team harnesses advanced ML algorithms to deliver automated, data-driven insights that continually adapt and evolve with your business.

From automating complex forecasting processes to uncovering hidden patterns in vast datasets, our solutions empower you to stay ahead of market changes, enhance the customer experience, and drive sustainable growth. We help you achieve:

- Greater accuracy and predictive power

- Reduced manual effort and faster decisions

- A competitive edge by transforming data into actionable insights

Tools & Technologies We Use

We leverage the best data analytics tools to predict the future and drive business success.

Qlik Predict™ helps analysts predict trends, understand causes, make proactive decisions and drive results – no coding needed.

Microsoft Azure provides storage, analytics, AI and more, enabling businesses to build, deploy and manage applications securely.

Forecast pro is an off-the-shelf forecasting package used across virtually all industries, enabling everyone to leverage sophisticated forecasting techniques.

Alteryx offers a leading AI Platform for Enterprise Analytics that delivers actionable insights by automating analytics.

Want to learn more?

What Our Clients Say

FAQs

What are the common challenges companies face with forecasting?

Companies often struggle with key questions such as:

🚀 How accurate is our forecasting? Can we improve it?

🚀 Are we using the most effective algorithms?

🚀 How can we reduce the time and effort required to generate forecasts?

🚀 How predictable is our product portfolio, and at which level?

🚀 Can additional external data enhance our forecast accuracy?

🚀 Is there a platform that integrates our forecasting process across teams while remaining cost-effective?

At WITSIDE, we address these challenges by offering end-to-end forecasting solutions that combine internal historical data with external (exogenous) data.

This approach significantly enhances the accuracy of forecasting models, providing businesses with actionable insights and measurable improvements.

What tools do you use for advanced analytics?

At WITSIDE, we leverage various advanced tools depending on the project requirements. These include:

🚀 AI and Machine Learning Platforms: Such as Microsoft Azure for predictive modeling and automation.

🚀 Data Integration & ETL Tools: Such as Alteryx for data preparation and integration.

🚀 Statistical Analysis Software: Including R and Python for data analysis, predictive modeling, and statistical algorithms.

🚀 Visualization Tools: Such as Qlik, Power BI, and Tableau to help stakeholders visualize insights and outcomes.

Which industries can benefit from advanced analytics?

Retail: For demand forecasting, customer segmentation, and personalized marketing.

Finance: For fraud detection, risk management, and customer retention.

Healthcare: For predictive diagnostics, patient care optimization, and operational efficiency.

Manufacturing: For predictive maintenance, supply chain optimization, and quality control.

Logistics: For routing optimization, demand planning, and efficiency improvements.

Telecommunications: For network optimization, customer churn prediction, and targeted marketing.

Do I need a data science team to implement advanced analytics in my organization?

Not necessarily. While having a dedicated data science team can accelerate adoption, it’s not a requirement. Many organizations can collaborate with a reliable advanced analytics company like WITSIDE to deploy Advanced Analytics solutions. This option reduces the need for deep in-house expertise, enabling business users to access advanced insights with the help of intuitive software and expert external support.

What is the difference between analytics and advanced analytics?

Analytics focuses on analyzing historical data to understand what happened and why. It typically includes descriptive and diagnostic methods, like basic reporting and data visualization.

Advanced Analytics goes beyond this, using predictive modeling, machine learning, and AI to forecast future trends, optimize operations, and recommend actions. It’s proactive, helping businesses not only understand past performance but also shape future outcomes.

What’s the difference between business intelligence and advanced analytics?

Business Intelligence (BI) primarily focuses on descriptive analytics, which looks at past and present data to understand what happened and present those insights via dashboards and reports.

Advanced Analytics, on the other hand, focuses on predictive and prescriptive analytics, using data to forecast future outcomes and recommend specific actions to optimize business processes. Advanced Analytics delves deeper than BI by uncovering patterns and making data-driven recommendations for future decisions.

What’s the difference between advanced analytics and artificial intelligence?

Advanced Analytics uses data analysis techniques like predictive modeling, machine learning, and statistics to forecast future trends and optimize decision-making.

Artificial Intelligence (AI) is a broader concept that refers to machines simulating human intelligence. AI can include machine learning, natural language processing, and automation, and Advanced Analytics often uses AI techniques to generate predictions and recommendations. Essentially, Advanced Analytics can be considered a specific application of AI to analyze data and drive business insights.

What's the difference between data science and advanced analytics?

Data Science is a broader field that encompasses the entire process of extracting insights from data, including data collection, cleaning, analysis, and interpretation. It involves a wide array of methods, including machine learning, artificial intelligence, and statistical modeling.

Advanced Analytics is a subset of Data Science focused specifically on sophisticated techniques like predictive modeling, optimization, and AI-driven decision-making analytics to drive business decisions and forecast future trends.

Business Intelligence

Transform complex data into intuitive, interactive dashboards that empower decision-makers to uncover actionable insights and drive business success with clarity and precision.

Data Management

Ensure data integrity, accessibility, and compliance with robust management strategies, unlocking the full potential of your data for smarter, more informed decisions.

AI-Driven Decision Making

Using advanced algorithms, machine learning, and simulation models, AI-driven decision-making analytics identifies the best courses of action for various scenarios. For example, it answers critical business questions like:

- What actions should we take to achieve the desired outcome?

- Which strategies will minimize risks while maximizing gains?

- How do we optimize our resources and processes in response to anticipated changes?

WITSIDE’s AI-driven decision-making analytics solutions are designed to help you confidently navigate the complex business landscape. For example, in supply chain management, AI-driven decision-making analytics can recommend the optimal inventory levels based on demand forecasts, supplier reliability, and delivery timelines.

In trade and campaign optimization, AI-driven decision-making analytics suggest a trade promo or marketing strategy to increase sales in the consumer goods industry (i.e., FMCG, health, etc.).

By analyzing multiple data points (both internal and external), our AI-driven decision-making models evaluate potential scenarios and provide clear recommendations on the best course of action. These recommendations are not static; they evolve as new data comes in, ensuring that your strategy remains flexible and adaptable in real time.

From resource allocation to pricing strategies, AI-driven decision-making analytics transform your data into clear, actionable strategies that drive business success.

Agent-AI & Auto-ML

What is AI?

Artificial Intelligence (AI) enables machines to mimic human thinking, reasoning, learning, and decision-making. By analyzing data through algorithms, AI powers technologies like speech recognition, image analysis, and predictive modeling. It’s reshaping industries from healthcare to finance with faster, smarter, more scalable solutions.

Agentic AI: Revolutionizing Autonomy in Decision-Making

Agentic AI (or Agentic Artificial Intelligence) refers to AI systems that operate as autonomous agents capable of independent decision-making, adaptive learning, and dynamic interaction with their environments. Unlike traditional rule-based AI, these agents:

🚀 Learn continuously from interactions and feedback,

🚀 Adapt to evolving conditions in real time,

🚀 Pursue goal-oriented actions without explicit programming.

By analyzing data, executing tasks, and refining strategies through feedback loops, Agentic AI excels in dynamic scenarios. Applications include personalized customer service, process automation, and AI-driven assistants that anticipate user needs. Its ability to navigate uncertainty and optimize outcomes makes it transformative for industries reliant on real-time decision-making, such as logistics, cybersecurity, and personalized healthcare.

What is Machine Learning (ML)?

Machine Learning enables systems to learn from data, recognize patterns, and make predictions, without being explicitly programmed. It’s the engine behind smarter decision-making and continuous optimization across business operations.

At WITSIDE, we use ML to automate complex data science tasks, reducing manual effort while boosting accuracy and insight.

Auto-ML: Scalable Data Science in Action

Auto-ML (Automated Machine Learning) accelerates the ML lifecycle by automating time-consuming tasks like data preparation, feature selection, and model tuning. This empowers teams to scale their analytics efforts with less technical overhead. Whether it’s predicting delivery times, identifying fraud, or personalizing customer experiences, Auto-ML makes advanced data science more accessible, even for teams with limited resources.

Combining human creativity with machine precision, Auto-ML helps businesses unlock faster, more reliable outcomes, turning data into real value.

Optimization Solutions

The performance of your supply chain and operations is crucial to your business’s success and competitiveness.

Optimization Solutions have never been more critical as companies strive to improve efficiency, reduce costs, and maintain flexibility amid constant market fluctuations and disruptions.

Supply chains involve diverse activities, from sourcing materials and manufacturing to distribution and reverse logistics. These activities cannot operate in silos; instead, they must be integrated into a cohesive, company-wide system that supports seamless operations across the entire business.

WITSIDE’s approach to Supply Chain and Operations Optimization revolves around data-driven insights and Advanced Analytics. We evaluate hundreds of scenarios side-by-side, enabling your team to make faster and smarter strategic decisions.

Our solutions build resilient, responsive supply chains that adapt to planned changes and unexpected disruptions. Through sensitivity analysis, we help you identify key tipping points in your supply chain, so you can proactively implement the best strategies and have alternative plans ready before challenges arise.

Key Areas of Optimization:

🚀 Safety Stock Minimization: We reduce excess stock while meeting demand, balancing holding costs and preventing stockouts.

🚀 Routing and Scheduling: We optimize logistics to cut costs, improve delivery times, and maximize resource efficiency.

🚀 Order Lead Time: We streamline procurement and production timelines to respond faster to market changes.

🚀 Network Optimization: We refine your distribution network, optimizing facility locations and transportation flows to reduce costs and enhance service.

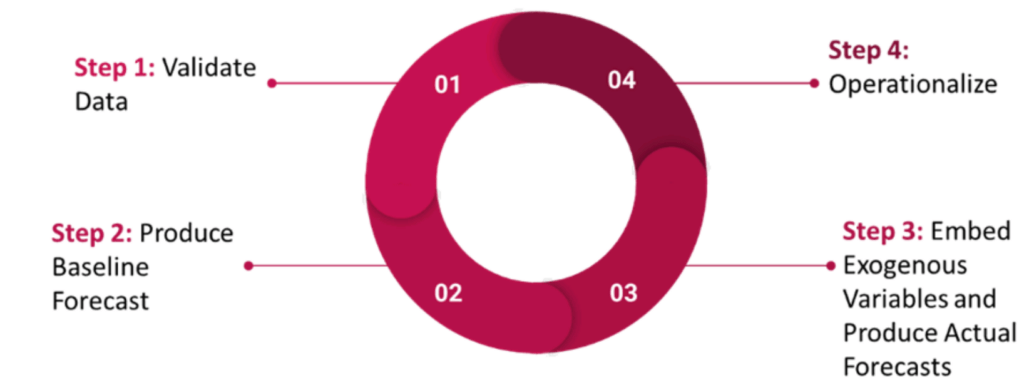

Forecasting

Chief Commercial Officers (CCOs) and Chief Operations Officers (COOs) depend on precise forecasting to meet demand efficiently, while optimizing raw material purchases at the best possible prices.

Chief Financial Officers (CFOs) rely on these accurate projections to effectively manage cash flow, ensuring that every operational decision is reflected in financial planning.

Predictive Analytics is at the heart of solving these critical challenges. Our unique framework is designed to address these needs through a seamless, four-step approach:

Step 1: Validate Data

We begin by validating the quality and relevance of the data, ensuring a strong foundation for accurate predictions. Clean, reliable data is essential for building robust forecasting models.

Step 2: Produce Baseline Forecast

Once the data is validated, we generate a baseline forecast using proven statistical methods and AI-driven algorithms, establishing a starting point for comparison and improvement.

Step 3: Produce Actual Forecasts

In this step, we enrich the baseline forecast with external factors such as market trends, economic indicators, or specific calendar events, allowing for a more comprehensive prediction model.

Step 4: Operationalize

Finally, we integrate the forecasting models into your day-to-day operations, creating an ongoing, dynamic forecasting system.